PROJECTS

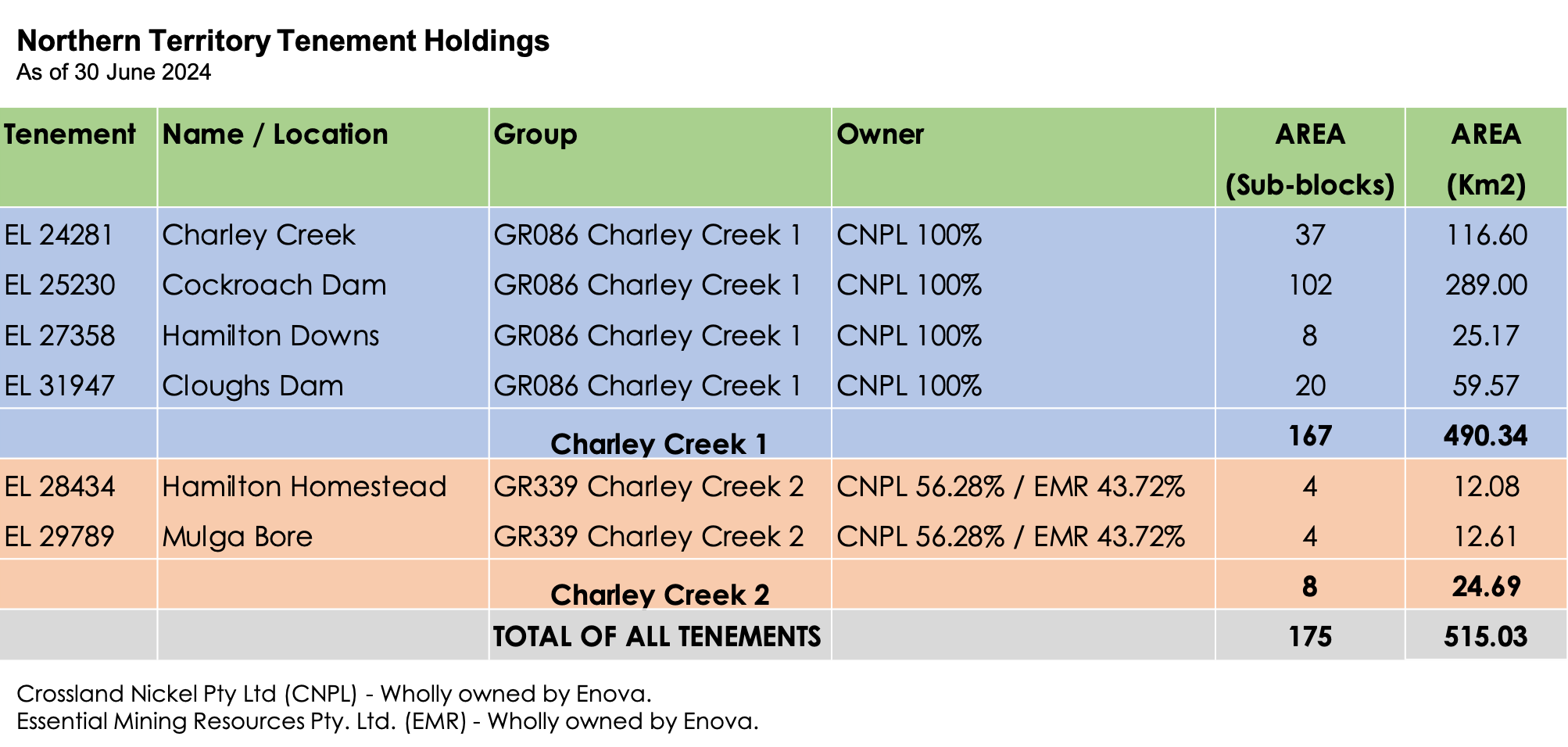

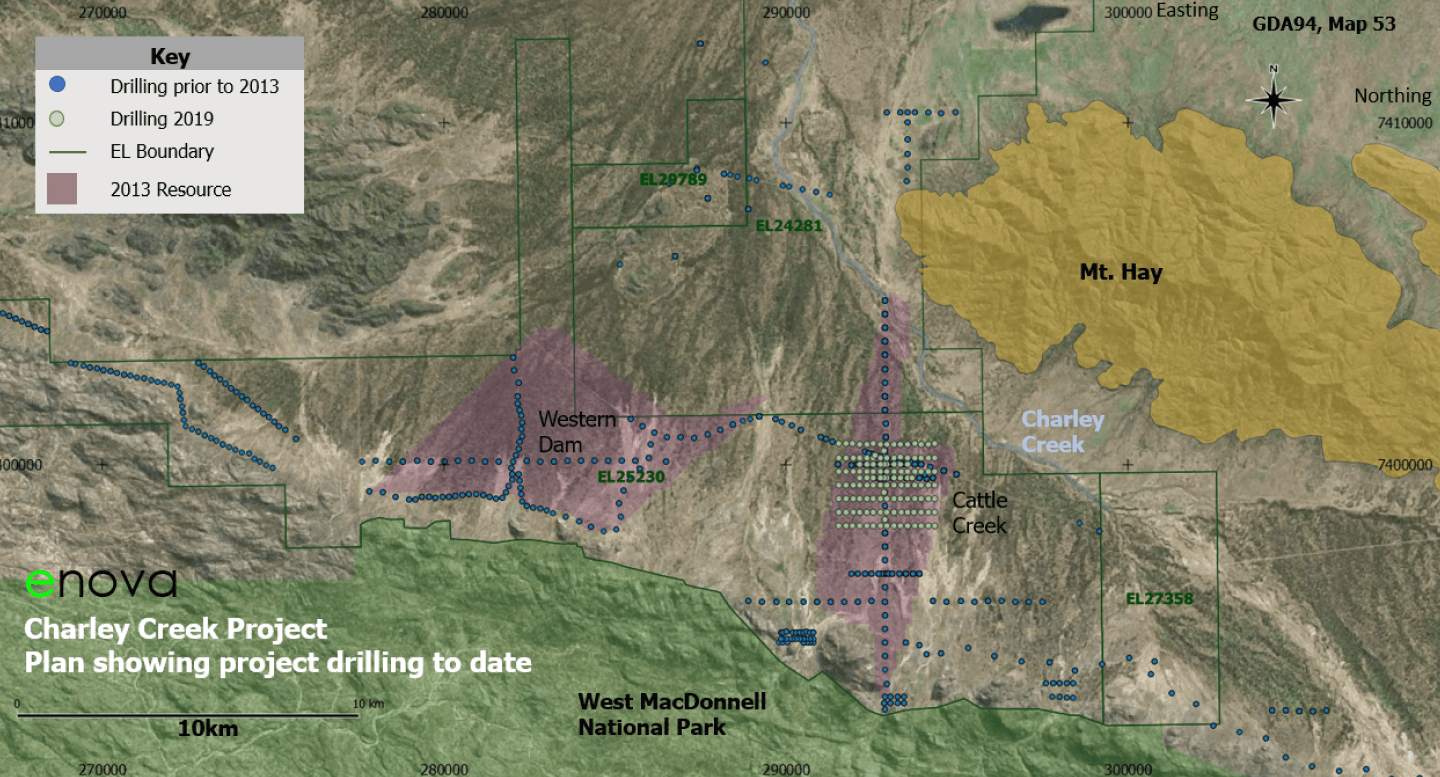

Charley Creek Project

Charley Creek Projects and Prospectivity

- Focus on developing the Cattle Creek prospect, as the flagship for the Charley Creek Project

- Large tenement, which is highly prospective area for rare earth mineralisation,

- No over-burden and geologically simple orebody that underpins potential open pit bulk mining concept

- Preliminary test work demonstrates that valuable rare earth minerals (monazite and xenotime) may be extracted using cost-effective gravity separation,

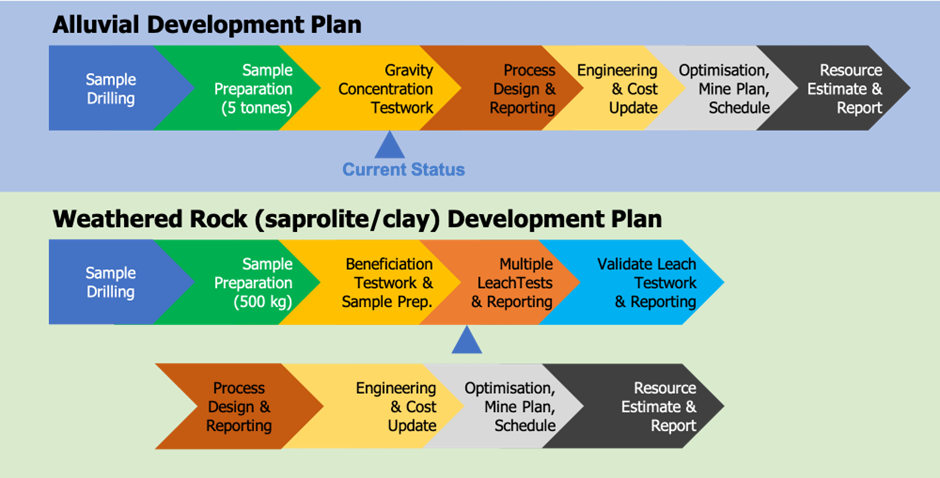

- Metallurgical process flow sheet optimisation test work is in progress for alluvial material, then advancing to bulk heavy mineral separation tests and concentrate cracking/leach testing,

- Resource and Scoping Study update planned for alluvial project in 2024,

- Western Dam prospect awaits resource drilling,

- Cattle Creek saprolite/puggy clay leaching tests for scandium and REE are in progress,

- Deep drilling is planned to assess the TREO potential of basement rock at Cattle Creek in 2024

- Metallurgical sampling and shallow drill testing planned for evaluation of elevated Rubidium at Cockroach dam area in 2024

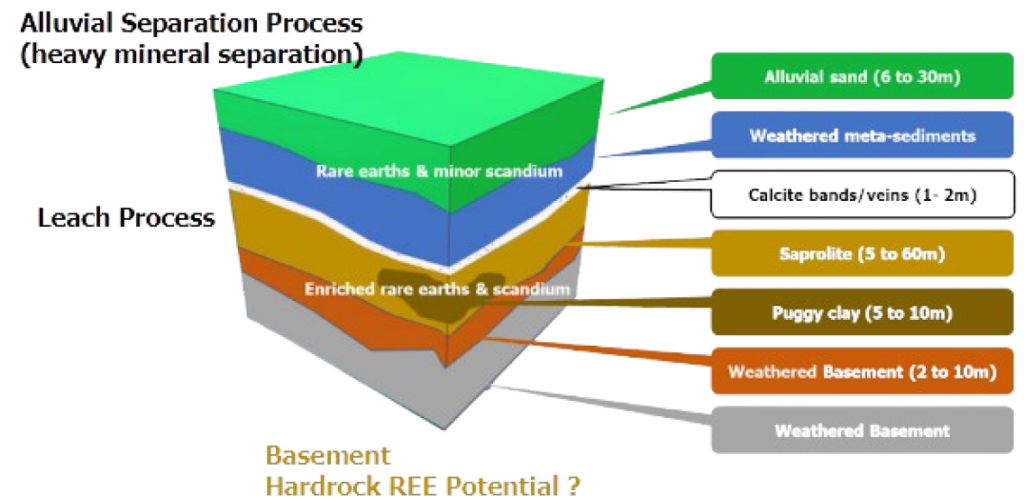

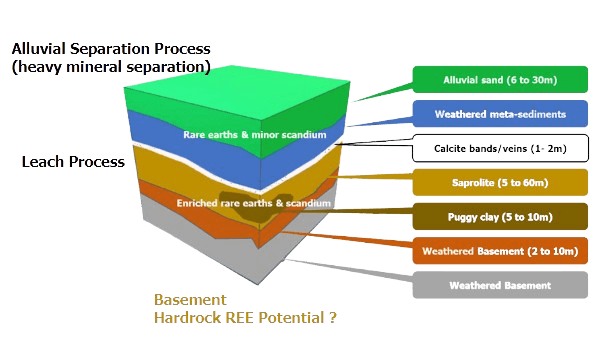

Charley Creek Geological Setting

The Charley Creek project area is dominated by the MacDonnell Ranges which trend east-west to the immediate south of the project tenements. The MacDonnell Ranges are an uplifted, tilted and dissected plateau of basement Proterozoic rocks comprising metasediments, mafic and felsic granulites, gneisses, migmatites and granites. To the south, Devonian sediments form the northern rim of the Amadeus Basin.

The northern boundary of the MacDonnell Ranges is marked by a major fault zone, the Redbank Thrust Zone. North of the Redbank Thrust Zone the basement rocks of the Arunta Block are largely buried beneath flat-lying plains, with occasional hills of basement rocks protruding through the younger sediments. The buried basement rocks commonly show a zone of saprolitic weathering, overlain by Tertiary sediments and calcrete, overlain in turn by Quaternary colluvial and alluvial gravels and sands, representing outwash fans from the weathering of the older basement rocks.

The basement rocks contain elevated values of uranium and thorium and are also the source of the rare earth minerals found in the Charley Creek alluvials. Drilling elsewhere has intersected up to 80m of Quaternary alluvial sands, gravels, meta-sediments and calcrete, the depth of mineralisation material varies across both Western Dam and Cattle Creek

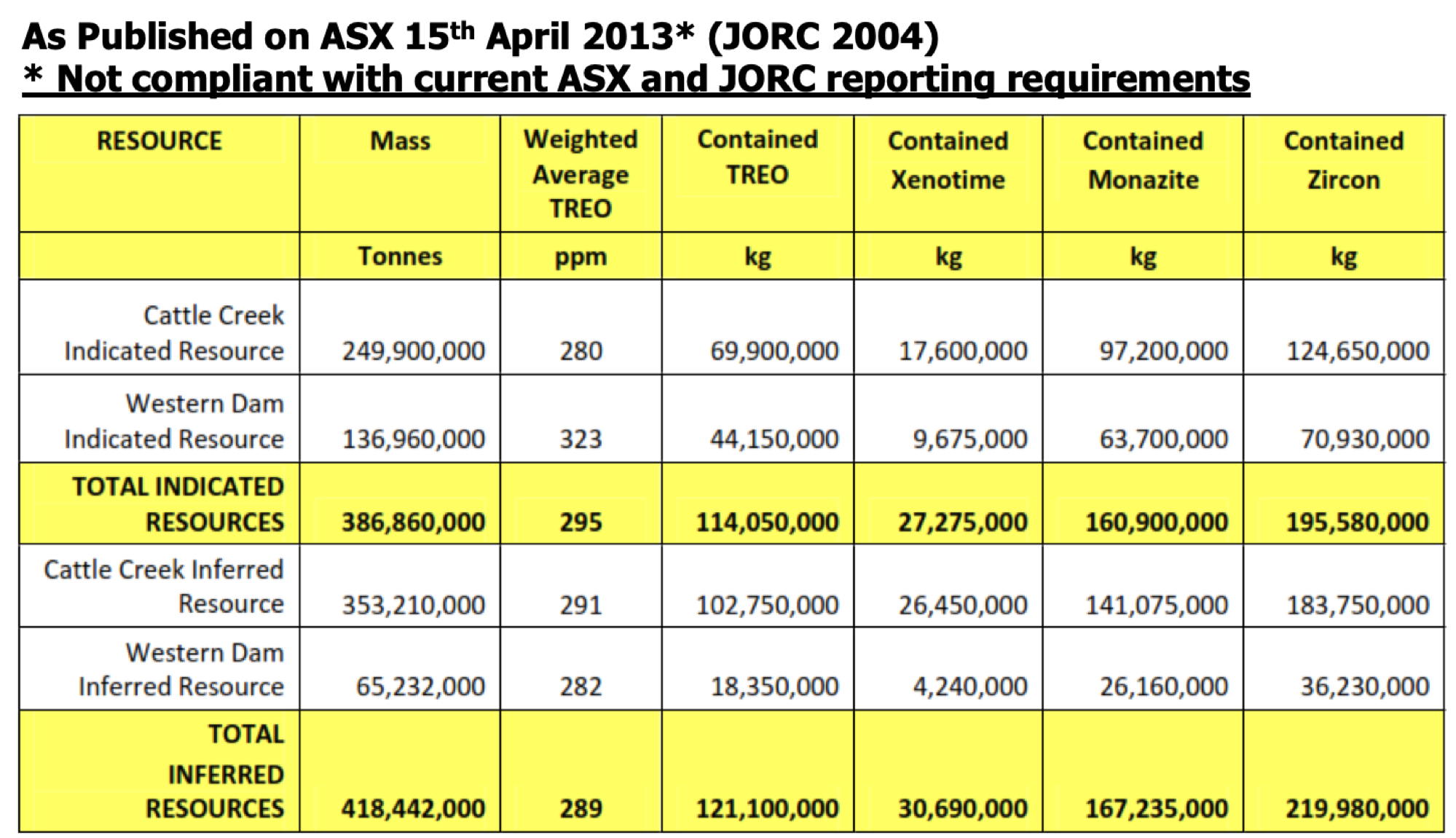

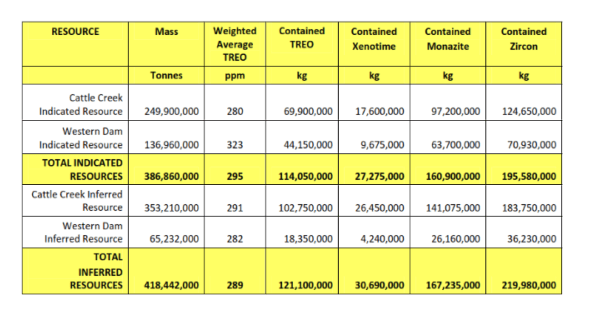

“This information was prepared and first disclosed under the JORC Code 2004. It has not been updated since to comply with the JORC Code 2012 on the basis that the information has not materially changed since it was last reported.”

Enova Mining Limited prioritizes robust corporate governance to ensure ethical and sustainable operations. Our governance framework is designed to uphold transparency, accountability, and integrity in all business practices. This includes stringent compliance with industry regulations, proactive risk management, and the promotion of responsible mining practices. The board of directors, comprised of experienced professionals, oversees strategic decision-making and monitors performance to align with stakeholders’ interests.

Enova Mining Limited prioritizes robust corporate governance to ensure ethical and sustainable operations. Our governance framework is designed to uphold transparency, accountability, and integrity in all business practices. This includes stringent compliance with industry regulations, proactive risk management, and the promotion of responsible mining practices. The board of directors, comprised of experienced professionals, oversees strategic decision-making and monitors performance to align with stakeholders’ interests.

- Focus on drilling Cattle Creek prospect, with most of the tenement area unexplored but highly prospective for mineralisation. Western Dam prospect awaits re-drilling,

- Near surface and simple orebody to underpin potential open pit bulk mining

- Preliminary test work demonstrates that valuable rare earths may be extracted via cost-effective gravity separation of the upper alluvial sands, and leaching from the saprolite clays

- Further drilling, gravity concentration testing and leach testing is progress

- Resource upgrade and Scoping Study planned for 2025

Scandium

- CODA South the highest assaying REE drill intercepts were recorded at end of hole: 0.5m @ 5,697 ppm TREO and 1m @ 5,078 ppm TREO

- To date auger drilling to 10m only, open at depth

RC drilling to commence June 2024

Scandium and The Future

Enova Scandium Market Strategy

Market scandium oxide as superior aluminium alloy, partnering with manufacturers:

- As a substitute for manufacturers currently using titanium products

- Requiring low failure rates for intricate casting

- For 3D additive printing media to produce, intricate, high tech, high performance parts

- For products requiring high performance materials; aerospace and hydrogen generation

- With exotic products and components, seeking exclusivity and marketing edge… motor vehicles

Market scandium oxide as superior aluminium alloy, partnering with material suppliers/custom smelter to:

- Work with custom alloy producers to offer product to market

- Ceate sample metals for key industry users and invite off-take participation

- Exclusivity by partnering with off-take agreement

Certainty of supply and market pricing will encourage new industry use by:

- Providing researchers with government support, for new green products using scandium

- Ceate sample metals for key industry users and invite off-take participation

- Encouraging government to incentivise industry to assess product substitution or new uses

What are the Next Steps?

Completion of Operation Concept & Resource Statement (update)

- Initial focus on the flag-ship Cattle Creek Prospect where the resource is best defined

- To date project is under-valued due to on-going test work which limited news releases

- Updated resource release will allow the market to reappraise the assets

- Expectation for Enova share price to adjust favourably.

Work Plan

- Alluvial Project :

- Bulk testing for Metallurgical optimisation

- Bulk scale lab “Proof of Concept” test to :

- Validate method by demonstration; screening, sizing, grinding, gravity concentration

- Recover heavy concentrate for further analysis

- Cracking/leach concentrates, produce solutions for analysis and REE SX simulation

- Economic modelling

- Resource modelling

- Pit optimisation and mine planning to ensure ore supply

- Process engineering and Mine Planning to complete RPEEE and update/publish resource statement Saprolite Project:

- Saprolite Project:

- Size beneficiation for leaching of ultra-fines, remove deleterious minerals and adsorption tests (SX and IX testing)

- Hydrometallurgical leach testing and verification

- Process concept and Costing (OPEX and CAPEX)